Boost your home's value with crown molding. Our pros share expert tips on materials, installation, and design ideas that make a real impact. Get your free quote!

Key Takeaways

- **MDF (Medium Density Fiberboard):** This is your budget option. Pre-primed MDF from brands like Metrie is easy to find. The downside? It's basically dust held together with glue. It doesn't hold a sharp edge, swells with any moisture, and dulls saw blades fast. We generally advise clients against it unless budget is the absolute top priority.

- **Polyurethane:** Lightweight options from Fypon look good from a distance and are great for intricate profiles. They won't rot or warp. But up close, they can look and feel a bit plasticky. For a home aiming for an authentic, premium feel, it sometimes falls short.

- **PVC (Plastic):** For bathrooms, basements, or any area with moisture, PVC trim like AZEK is the only way to go. You can't beat its resistance to mold, mildew, and rot. It paints up nicely and holds its shape no matter the humidity.

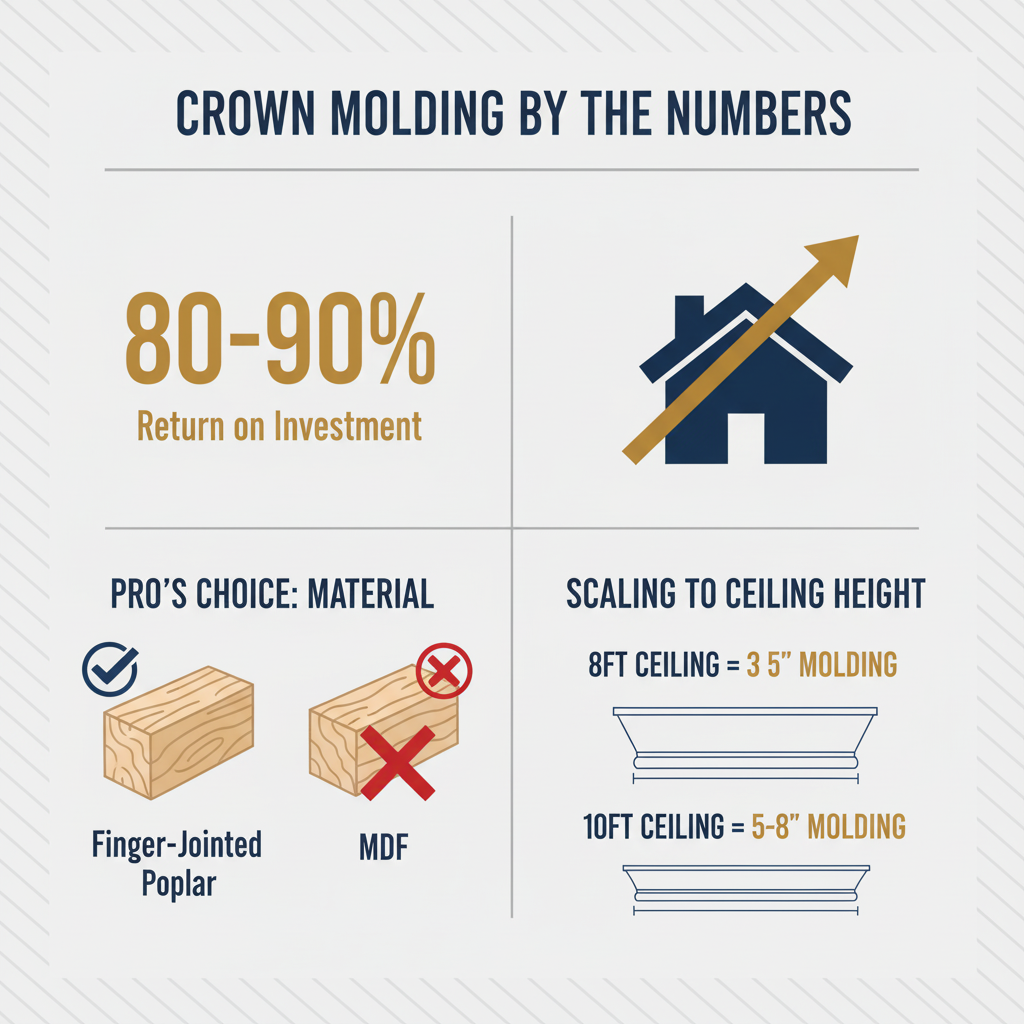

- **Poplar (Our Top Pick):** For most interior painted applications, our team relies exclusively on finger-jointed poplar. It's a real hardwood that's more stable than solid pine, meaning fewer gaps over time. It cuts cleanly, creating the crispest corners and joints. It simply delivers a milled-wood finish that MDF can't touch.

Key Takeaways

Crown Molding: A Pro's Guide to a Flawless Finish

Crown molding is that one final touch. It's the detail that separates a nice room from a truly stunning one. It creates a graceful transition between your walls and ceiling, adding a layer of sophistication that just wasn't there before. Frankly, it makes a space feel finished.

But slapping up some trim from the hardware store isn't going to cut it. The difference between a DIY job and a professional one is massive. We're talking crisp corners, invisible seams, and a design that actually fits the room. Let's walk through how our pros get it right every time.

What Makes Crown Molding a Smart Upgrade?

Crown molding adds immediate architectural character and makes any room feel more complete and valuable. Our team consistently sees it boost a home's market appeal by concealing imperfections at the wall-ceiling joint and providing a polished, high-end finish that elevates the entire space.

Look, builder-grade homes often feel a bit plain. They lack character. Here's where trim work really shines. It's not about making your home look like a Victorian mansion (unless you want that!). It's about adding intentional detail. We transformed a home in Denver just last month that went from a simple boxy living room to an elegant space, just by adding properly scaled molding. The homeowner couldn't believe the difference—it really does transform everything.

Which Trim Material is Best for Your Home?

Your best trim material depends on your budget, the room's conditions, and whether you plan to paint or stain the wood. Our licensed painters prefer finger-jointed Poplar for painted projects due to its stability and sharp look, while PVC is the undeniable champion for bathrooms and basements.

Choosing the right material is a huge part of the battle. Honestly, what you pick can make or break the project's longevity.

- **MDF (Medium Density Fiberboard):** This is your budget option. Pre-primed MDF from brands like Metrie is easy to find. The downside? It's basically dust held together with glue. It doesn't hold a sharp edge, swells with any moisture, and dulls saw blades fast. We generally advise clients against it unless budget is the absolute top priority.

- **Polyurethane:** Lightweight options from Fypon look good from a distance and are great for intricate profiles. They won't rot or warp. But up close, they can look and feel a bit plasticky. For a home aiming for an authentic, premium feel, it sometimes falls short.

- **PVC (Plastic):** For bathrooms, basements, or any area with moisture, PVC trim like AZEK is the only way to go. You can't beat its resistance to mold, mildew, and rot. It paints up nicely and holds its shape no matter the humidity.

- **Poplar (Our Top Pick):** For most interior painted applications, our team relies exclusively on finger-jointed poplar. It's a real hardwood that's more stable than solid pine, meaning fewer gaps over time. It cuts cleanly, creating the crispest corners and joints. It simply delivers a milled-wood finish that MDF can't touch.

The #1 Mistake We See Amateurs Make

So many DIY projects fail at the 'termination point.' What happens when the molding stops, like over a cabinet or on a partial wall? Amateurs often just cut it flat. It looks awful and unfinished. In our experience, most homeowners completely miss this detail—and it's what separates the pros from the weekend warriors. Our team creates a 'return'—a tiny, mitered piece that turns the molding's profile back into the wall. Sounds like a small thing, right? But it screams high-end craftsmanship.

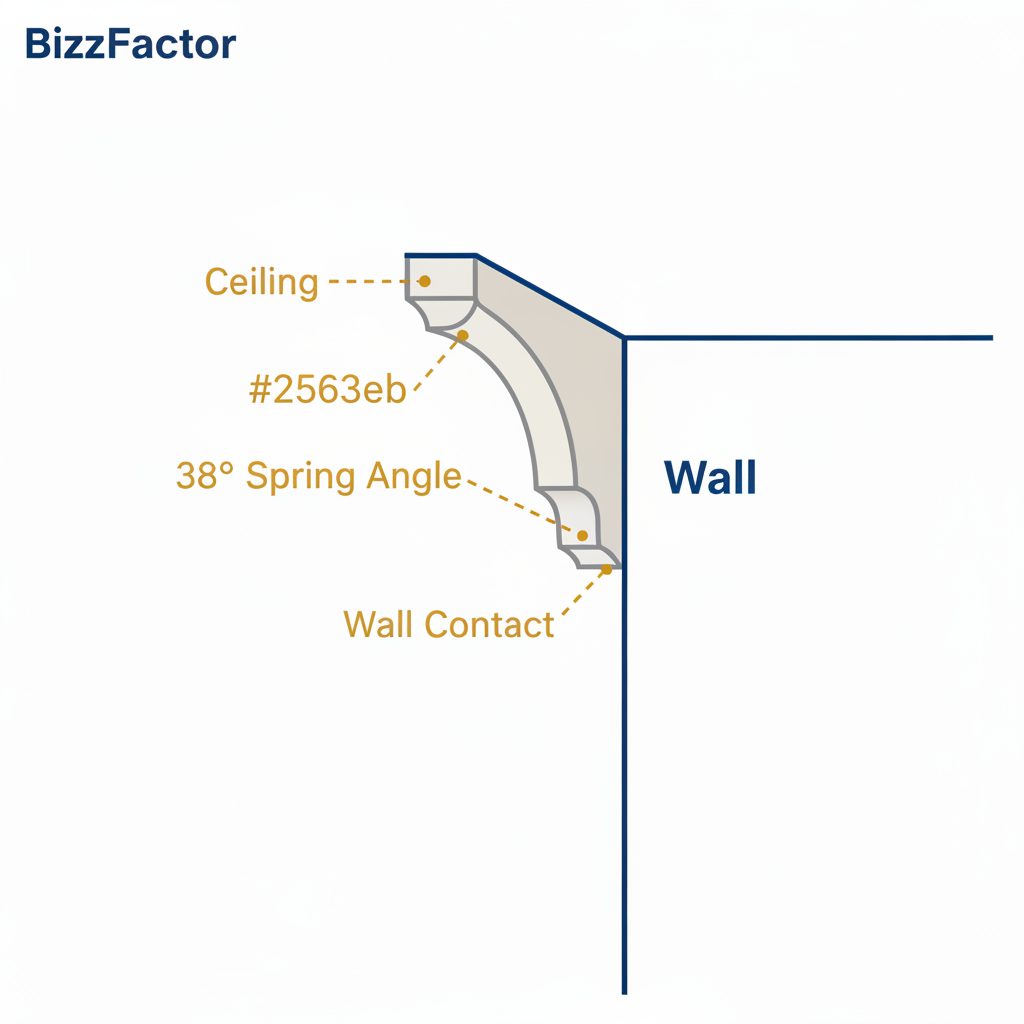

How Should You Position Trim for Best Results?

Positioning trim for the best results means scaling it to the room's ceiling height and size. Our rule of thumb for standard 8-foot ceilings is crown molding between 3 to 5 inches tall. For taller 9 or 10-foot ceilings, we scale up to 5 to 8 inches to maintain a pleasing visual balance.

Proportions are everything. A huge crown molding in a small room with low ceilings will feel oppressive. Too-small molding in a grand two-story living room will just look silly and get lost. It's an art and a science that our designers, with over 20 years of experience, have perfected.

Here's a pro secret most guides won't tell you: for a modern, sophisticated look, try 'color drenching.' Paint the crown molding the exact same color *and* sheen as the walls. Instead of a stark white line, you get a beautiful, textured transition that makes the room feel taller and more cohesive. It emphasizes the *form* of the molding, not just its color.

What's the Professional Installation Process?

Professional installation ensures your trim looks flawless for years. Our process involves precise measurements, perfect miter cuts with professional-grade saws, and using both adhesive and nails to secure the molding. Our certified technicians then caulk, fill, and sand every seam for a truly seamless finish.

Here's how our team guarantees a perfect result:

1. **Preparation and Acclimation:** We let the wood acclimate in your home for at least 48 hours. This prevents shrinking and expanding after it's on the wall.

2. **Precise Measurements & Cuts:** Using a laser level and a high-quality compound miter saw (our pros love the DeWalt DWS780), we ensure every angle is perfect. We prefer 'coping' inside corners, a technique that provides a much tighter fit than a simple miter.

3. **Secure Fastening:** We use a strong construction adhesive like Loctite PL Premium on the back of the trim. Then, we use an 18-gauge pneumatic nailer to secure it to the studs. This combination is bulletproof.

4. **Flawless Finishing:** Here's where the magic happens. We fill every nail hole, caulk every seam with a flexible caulk like DAP Alex Plus, and then sand everything smooth before applying a furniture-quality paint finish, like Sherwin-Williams ProClassic.

Is Crown Molding Worth the Investment?

Crown molding is absolutely worth the investment, often returning 80-90% of its cost in increased home value. It's one of the most effective cosmetic upgrades our team performs. It provides the custom, high-end detail that helps a property stand out to potential buyers in a competitive market.

Think about it. In a neighborhood of similar houses, the one with beautifully executed trim work is the one that feels more expensive and better maintained. Recent surveys from the National Association of Realtors confirm what we see every day—interior design upgrades are a top priority for buyers.

How Do You Maintain Crown Molding?

Great news! When installed correctly by pros, crown molding needs very little maintenance. Because our team uses stable materials and flexible caulk, you shouldn't see much joint separation (the key is all that prep work).

We recommend a quick visual inspection once a year. If you spot any tiny cracks or nail pops—which can happen as a house settles—a quick touch-up is easy. We always leave our clients with a detailed record of the exact paint products used (brand, color, and sheen) to make future touch-ups a perfect match. A little effort upfront saves you a huge headache down the road.

In-Depth Look

Detailed illustration of key concepts

Visual Guide

Infographic illustration for this topic

Side-by-Side Comparison

Visual comparison of options and alternatives

Sources & References

- 10 'Old' Decor Trends That Have Made a Surprising Comeback

- 6 'old-fashioned' decorating techniques that designers still swear by

- The Beginner's Guide to Vintage Home Decorating: Where to Start

- Interior Designers Share Their Best Traditional Design Tips - Forbes

- Design Trends from the Past that are Making a Comeback

- Best Interior & Exterior Paint Buying Guide

- Best Paint for Commercial Buildings

- Best Industrial Painting Brands: A 2025 Comparison Guide

- Building Codes, Standards, and Regulations: Frequently ...

- PCA Industry Standards - Made Possible by the ...

Need Professional Help?

Find top-rated house painters experts in your area