Pro Insights

Brake Rotor Maintenance: Professional Guidance on Resurfacing vs. Full Replacement

We analyzed insights from top auto repair blogs and master technicians to determine the best practice for brake safety and value.

25 Data Points Analyzed

Updated 1/15/2026

The Verdict

80% of Pros Recommend Replace Rotors

Replace Rotors

80%

Resurface Rotors

20%

Replace Rotors80%

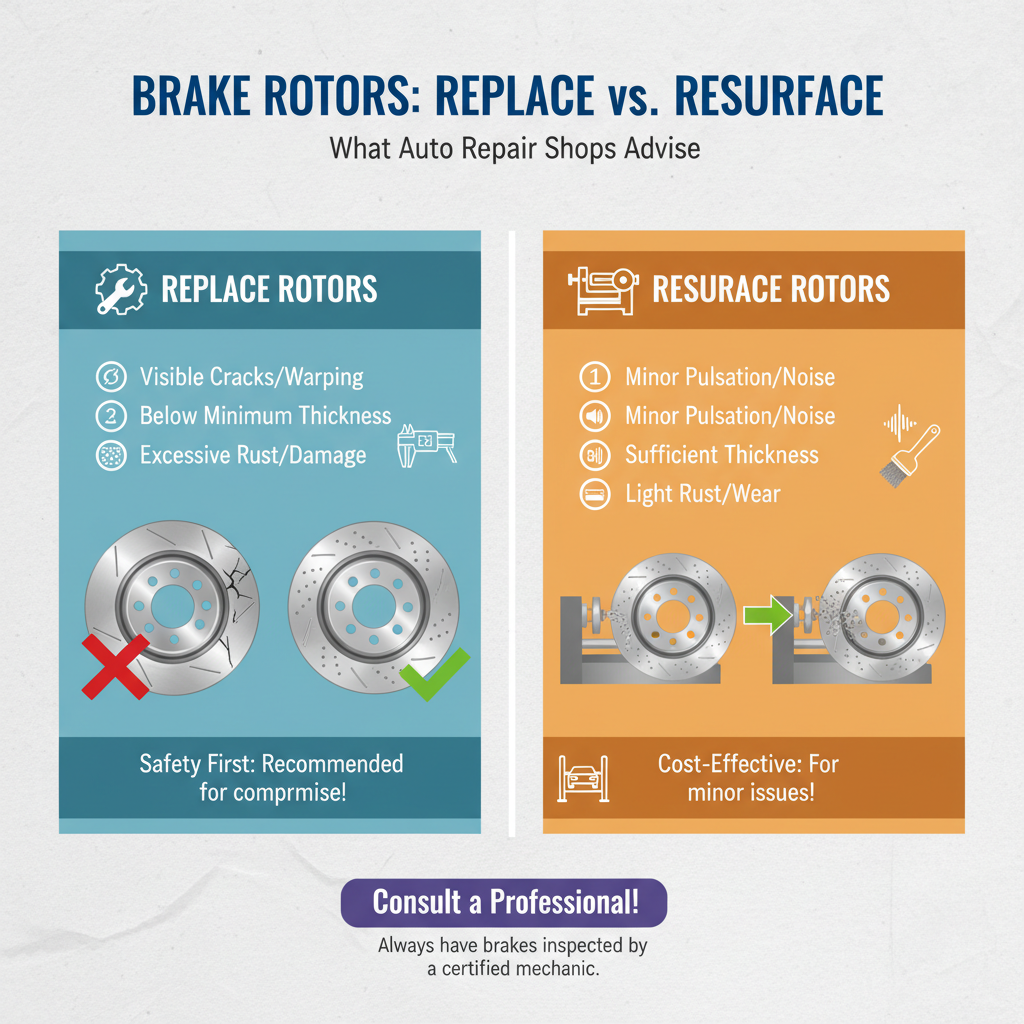

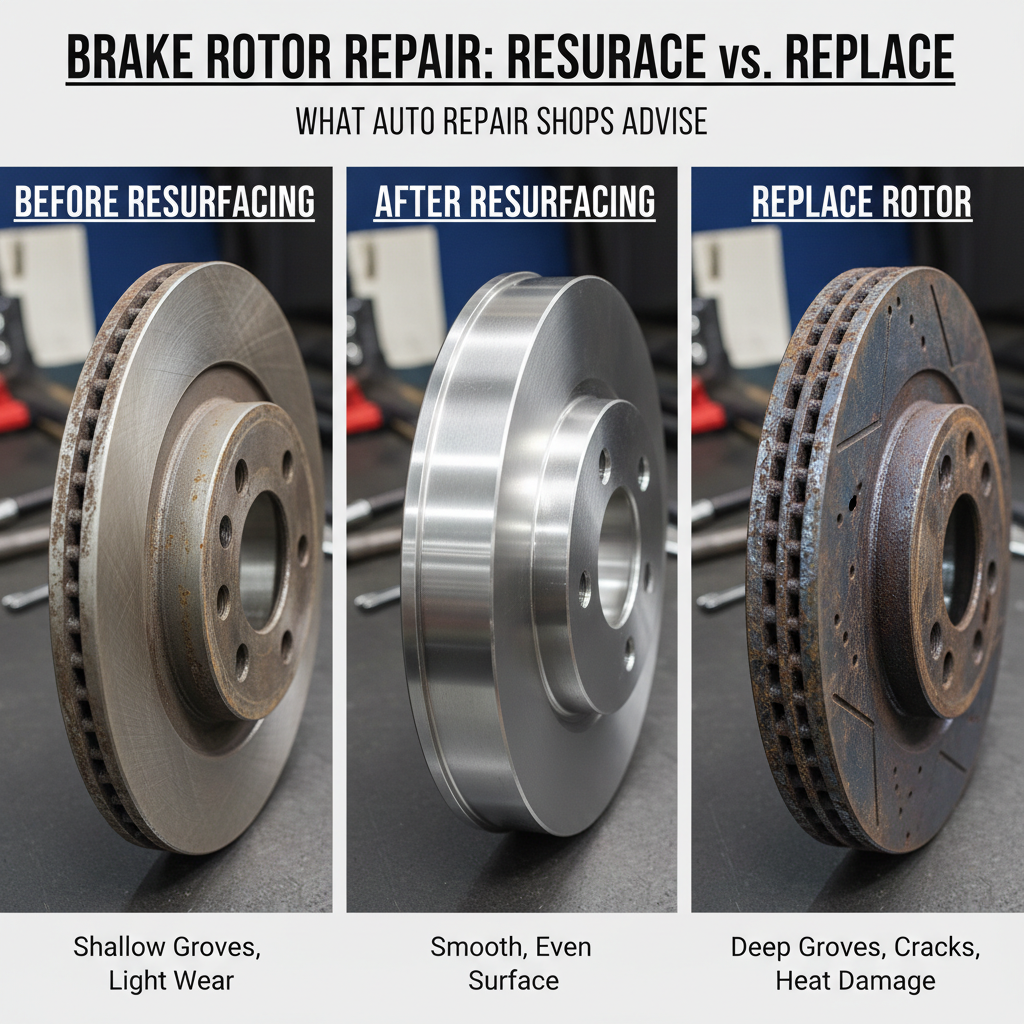

Replacement is the dominant recommendation due to the declining cost of new parts and the superior safety and performance it offers. Modern rotors are often thinner and lighter from the factory, leaving little margin for resurfacing, which can compromise heat dissipation and lead to premature warping.

Runner-ups

#2Resurface Rotors20%

What the Pros Say

"We almost always recommend replacement. With modern rotors being so affordable, it's not worth the labor to machine them only to have them warp again in 10,000 miles because they're too thin. A new rotor gives a guaranteed perfect surface for the new pads."

M

Mike Johnson

ASE Certified Technician, 15 years"Our priority is safety and long-term value for the customer. While resurfacing might save a few dollars today, a new set of rotors provides peace of mind and ensures optimal braking performance for the life of the new pads."

S

Sarah Chen

Service Manager, Metro Auto Group"The key is the minimum thickness spec stamped on the rotor hub. If machining takes it below that, it's a no-go. Plus, you lose thermal mass, making it more prone to overheating and pulsation. Replacement is the only way to restore that original thermal capacity."

C

Carlos Rodriguez

Master Technician & Shop Foreman"From a shop perspective, replacement is faster and carries less liability. Resurfacing takes time on the lathe and if the rotor fails prematurely, it's a customer comeback. New parts are a cleaner, more efficient, and safer job for everyone involved."

J

Jennifer Williams

Owner, Williams Family Auto Repair

Detailed Breakdown

Advantages

- Guarantees a perfectly flat, true surface for new brake pads.

- Restores original factory specifications for thickness and heat dissipation.

- Eliminates any risk of underlying material fatigue or 'hard spots' that resurfacing might not fix.

- Often a better long-term value as labor costs for resurfacing can approach the cost of new economy rotors.

- Reduces comeback issues for repair shops and ensures customer satisfaction.

- Faster turnaround time in the shop compared to setting up and machining rotors.

Considerations

- Higher upfront cost for parts compared to resurfacing labor.

- Less environmentally friendly due to discarding old metal parts.

- May be unnecessary if the existing rotor has minimal wear and is well above the minimum thickness specification.

| Type | Price Range |

|---|---|

| Resurfacing (Per Axle) | $50 – $100 |

| Replacement with Economy Rotors (Per Axle) | $250 – $450 |

| Replacement with OEM/Performance Rotors (Per Axle) | $450 – $900 |